Valve Guide Tools: Precision Tools for Optimal Engine Function

Jan 23rd 2025

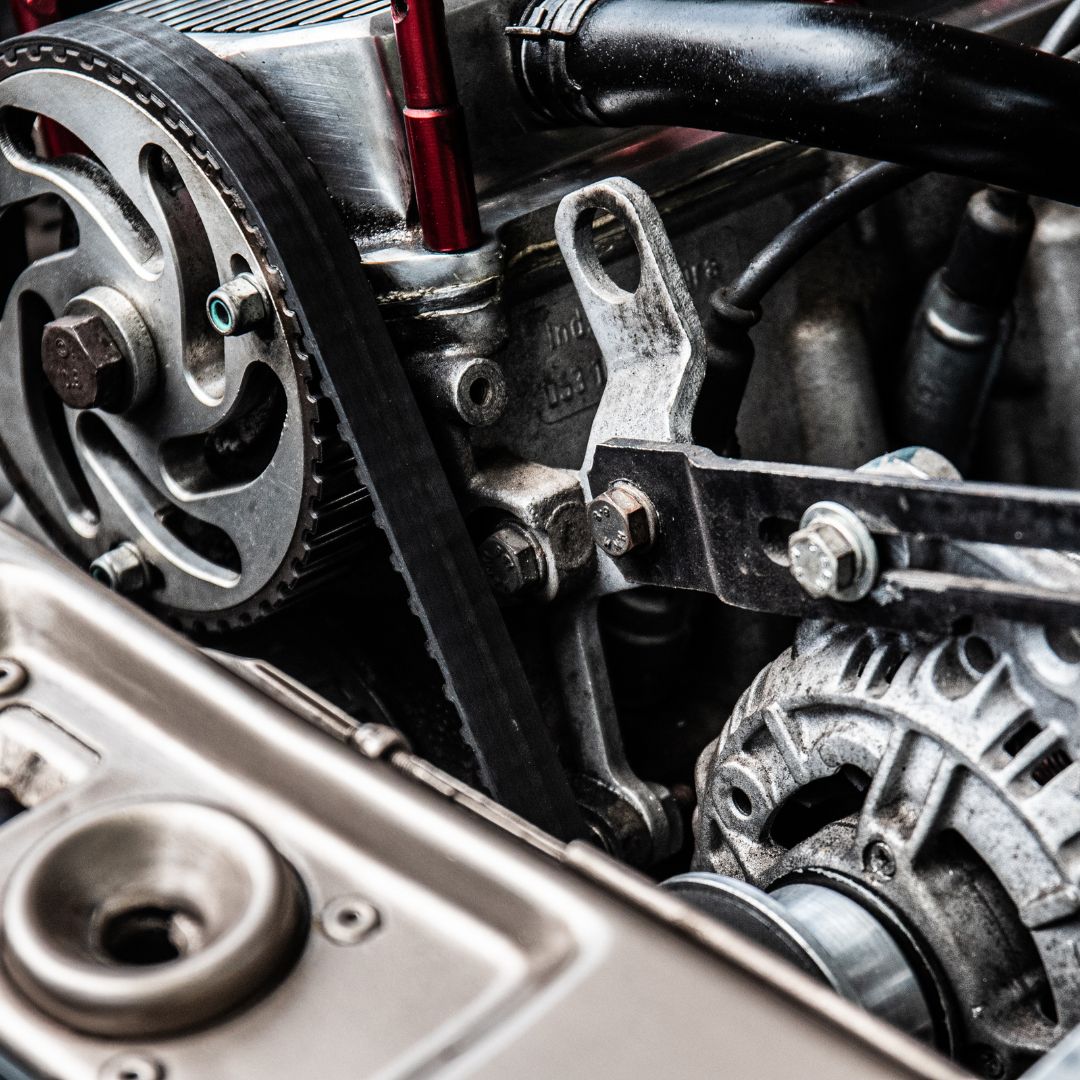

In engine design and maintenance, the precision of individual components is crucial for optimal engine function. Valve guide tools are essential for ensuring that valves operate smoothly within an engine. Poorly aligned or improperly fitted valves can lead to increased wear, decreased performance, and even catastrophic engine failure. At Regis Manufacturing, we understand the significance of using high-quality valve guide tools to maintain the integrity of your engine and enhance valve maintenance processes.

The Role of Valve Guide Tools

Valve guide tools are specialized instruments designed to help ensure that valve guides fit accurately and securely within the engine cylinder head. These precision engine tools enable mechanics to measure and align valve guides effectively, which promotes proper valve seating and reduces friction. By employing valve guide tools during installation or repairs, technicians can extend the overall lifespan of the engine components and maintain optimal engine function.

Enhancing Engine Function with Precision Tools

The impact of precision on engine function cannot be overstated. With accurate valve alignment facilitated by valve guide tools, the engine operates more smoothly, allowing for better airflow and combustion efficiency. This, in turn, maximizes power output and fuel economy. Regis Manufacturing's state-of-the-art precision engine tools focus on providing mechanics with the means to achieve optimal valve guide installation, thus enhancing the overall performance of the engine.

The Benefits of Regular Valve Maintenance

Incorporating valve guide tools into regular maintenance practices is a game-changer for engine longevity. Schedule routine checks using precision tools to monitor valve guide condition, ensuring that they remain free from wear and damage. Regular valve maintenance not only promotes smoother operation but also helps identify potential issues before they escalate, thus preventing costly repairs and improving overall engine reliability. At Regis Manufacturing, we advocate for the integration of valve guide tools in your maintenance toolkit to ensure that your engine runs at its best.

Choosing the Right Valve Guide Tools

Selecting the right valve guide tools can make a significant difference in your engine maintenance outcomes. Look for tools that are manufactured with high-quality materials and precise engineering standards. Our valve guide tools at Regis Manufacturing are designed for durability and accuracy, ensuring that technicians have the best tools at their disposal. Our range includes reamers, pilots, and bushings, all crafted to meet the highest performance standards, thereby supporting effective valve maintenance and engine function.

The Margin of Error in Valve Work

Even small misalignments in valve guides can lead to substantial engine issues over time. Valve guide tools mitigate this risk by providing precise measurements and alignment during installation. The ability to measure tolerances accurately gives mechanics the confidence to perform high-quality work. By investing in precision engine tools, you can significantly reduce the margin of error in valve work, ultimately leading to greater engine performance and longevity.

Optimize Engine Performance with Precision Valve Guide Tools

In the world of engine maintenance, the significance of valve guide tools cannot be overlooked. These precision tools ensure that valve guides fit accurately, thereby optimizing engine function and performance. Regular valve maintenance, facilitated by high-quality valve guide tools from Regis Manufacturing, enhances the overall longevity and reliability of your engine. Don’t leave your engine's performance to chance—choose precision. Contact us today to explore our range of valve guide tools and elevate your engine maintenance practices!