Unlocking Engine Power: A Guide to Porting and Polishing Cylinder Heads

Oct 15th 2025

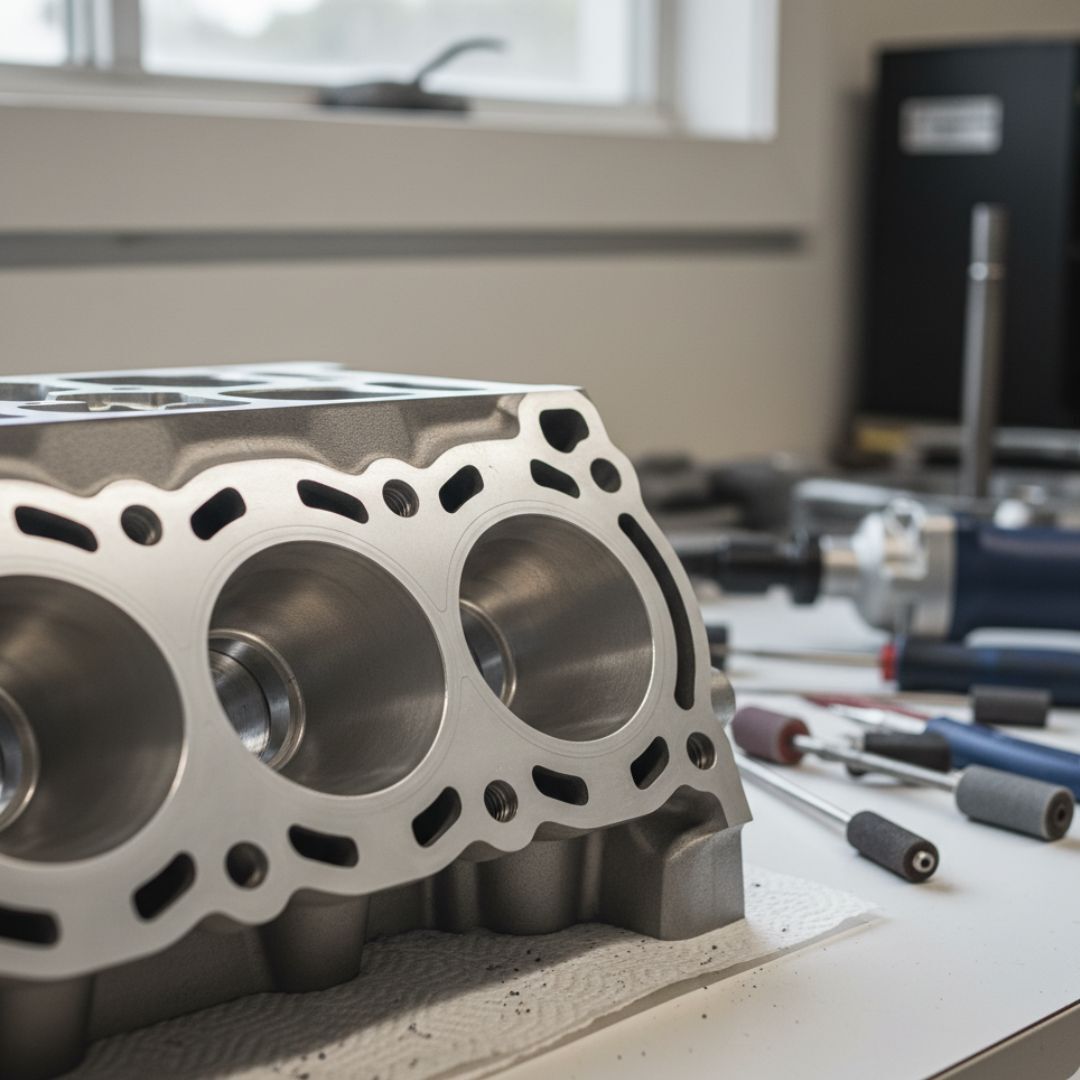

Here at Regis Manufacturing, we know that for engine builders seeking to extract every bit of potential from an engine, mastering cylinder head porting and polishing is a critical skill. This intricate process involves reshaping and smoothing the intake and exhaust ports to optimize airflow, leading to significant gains in horsepower and torque. It’s a delicate art that requires patience, precision, and the right equipment.

Understanding the Fundamentals of Airflow

The core principle behind porting is simple: an engine is essentially an air pump. The more efficiently we can move the air-fuel mixture into the cylinders and the exhaust gases out, the more power it can generate. By carefully removing casting imperfections and reshaping port walls, we reduce restriction and improve volumetric efficiency for a stronger-running engine.

Essential Tools for Precision Porting

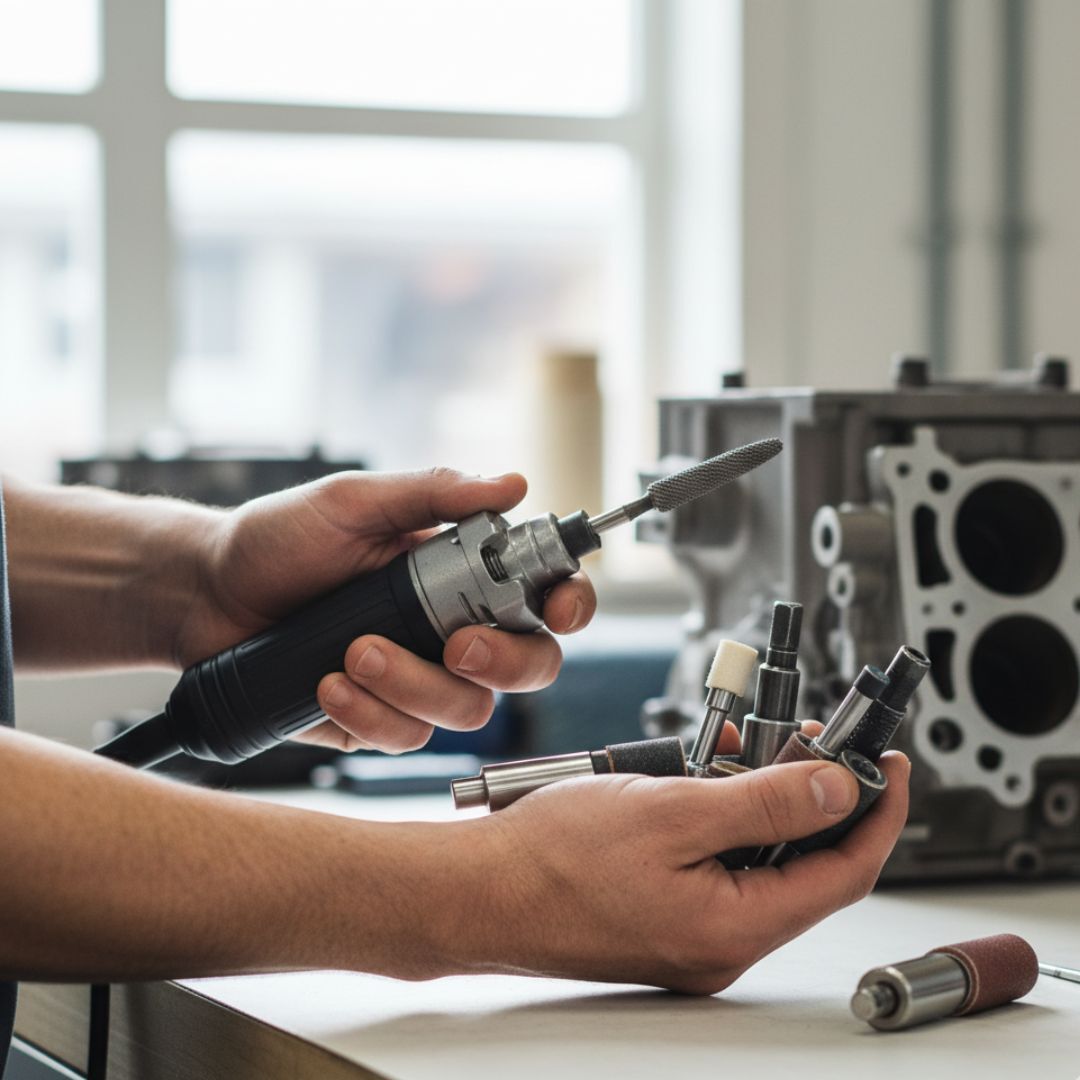

Achieving professional results requires specialized tools designed for control and accuracy. High-speed die grinders paired with quality carbide burrs are essential for reshaping the ports and bowls. Afterward, various cartridge rolls and sanding mandrels are used to achieve the desired surface texture. Having the correct selection of tools ensures you can tackle any port shape effectively.

The Art of Polishing for Optimal Flow

While a mirror finish isn't always the goal, proper polishing is crucial for reducing air and fuel turbulence within the ports. A smoother surface, particularly on the exhaust side, helps prevent carbon buildup and encourages more efficient gas flow. The objective is to create a uniform surface that guides the air-fuel mixture with minimal disruption.

Common Pitfalls to Avoid During the Process

One of the biggest risks in porting is removing too much material, which can break through to a water jacket and ruin the cylinder head. It’s also possible to alter the port shape in a way that hurts airflow rather than helping it. We always advise starting conservatively and focusing on consistency across all ports.

Your Partner in Precision Engine Work

Ultimately, porting and polishing is a rewarding process that can unlock your engine’s true performance potential. With the right techniques and a focus on detail, you can achieve significant improvements. For the high-quality burrs, sanding rolls, and other specialized supplies you need, explore our porting and polishing tools. Contact our knowledgeable team if you have questions about selecting the right tools for your project.