Rod & Piston Work: Enhancing Engine Performance and Longevity

Oct 8th 2024

In the realm of automotive performance, the intricate dance between rod and piston work plays a pivotal role in maximizing engine efficiency and longevity. As enthusiasts and professionals alike understand, the engine is truly the heart of any performance vehicle, and optimizing its components is crucial for achieving peak performance. In this blog from Regis Manufacturing in Dallas, Texas, we will delve into critical aspects of rod and piston work that can enhance engine performance and longevity.

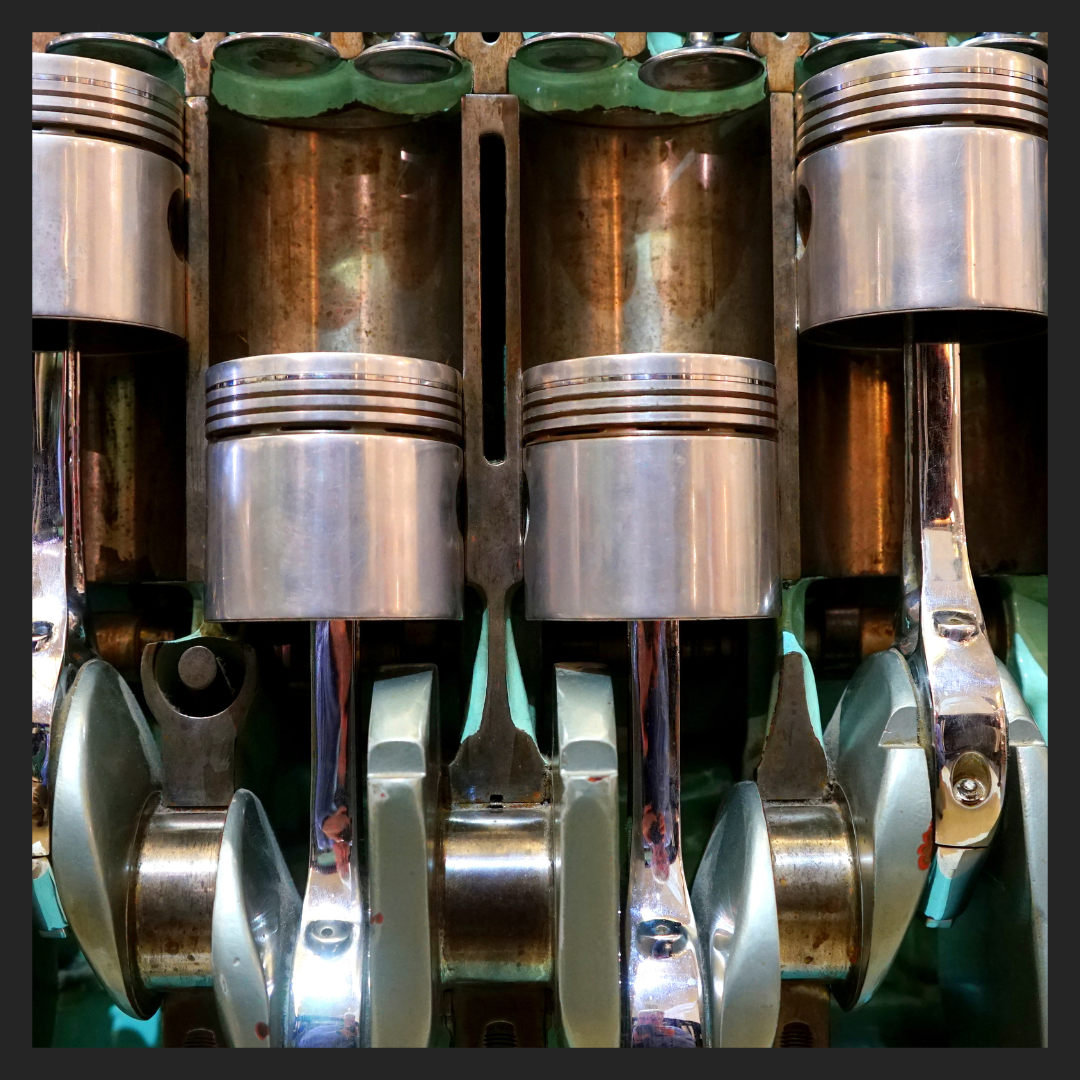

Precision Engineering of Connecting Rods

Connecting rods serve as the vital link between the pistons and the crankshaft, and their design significantly impacts the engine's performance. Rod work involves meticulously modifying or replacing these components to reduce weight and improve strength. Lightweight materials, such as high-grade aluminum or forged steel, can minimize reciprocating mass, allowing for quicker acceleration and increased RPMs.

Moreover, ensuring correct rod length and alignment prevents engine knock and promotes smooth operation. This precision engineering not only enhances immediate performance but also contributes to long-term durability by reducing stress on the engine's components.

Optimal Piston Design and Configuration

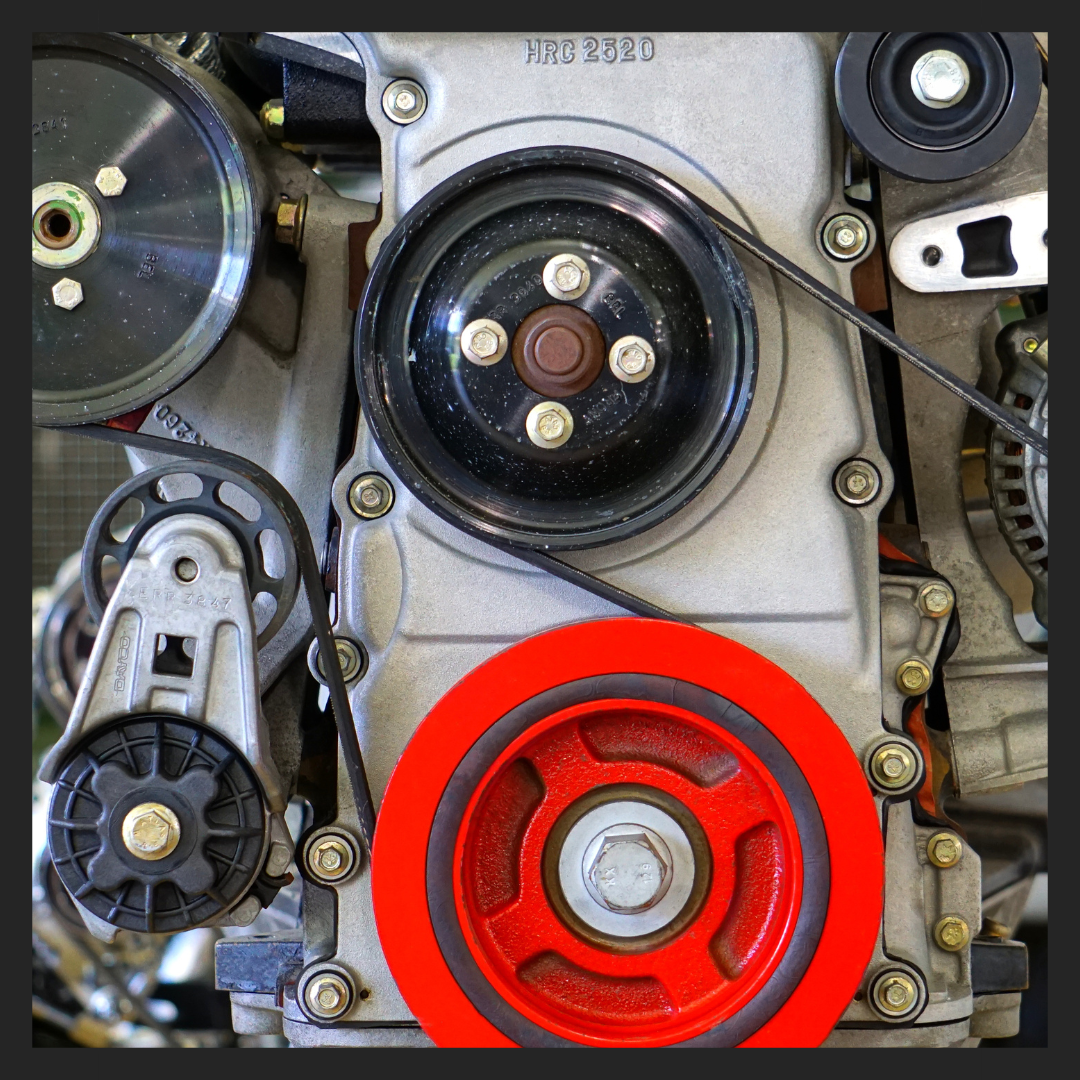

The pistons themselves are critical to the engine's combustion process. Piston work encompasses various modifications, including changes to piston shape, diameter, and ring design. Performance pistons, often crafted from advanced alloys, can withstand higher temperatures and pressures, thus improving thermal efficiency and reducing the likelihood of detonation. Additionally, optimizing piston ring configuration—from the sealing characteristics to the material used—can lead to substantial improvements in engine performance and longevity.

Balancing and Blueprinting the Engine

A thorough balancing process is crucial to achieving optimal engine performance. Rod and piston work must be harmoniously integrated to ensure that the engine operates smoothly at various RPMs. Blueprinting involves ensuring that all components—rods, pistons, and crankshaft—are manufactured to precise tolerances. This meticulous process mitigates vibration, which can lead to premature wear and tear. By fine-tuning the assembly, enthusiasts can achieve higher RPMs without excess stress on the engine.

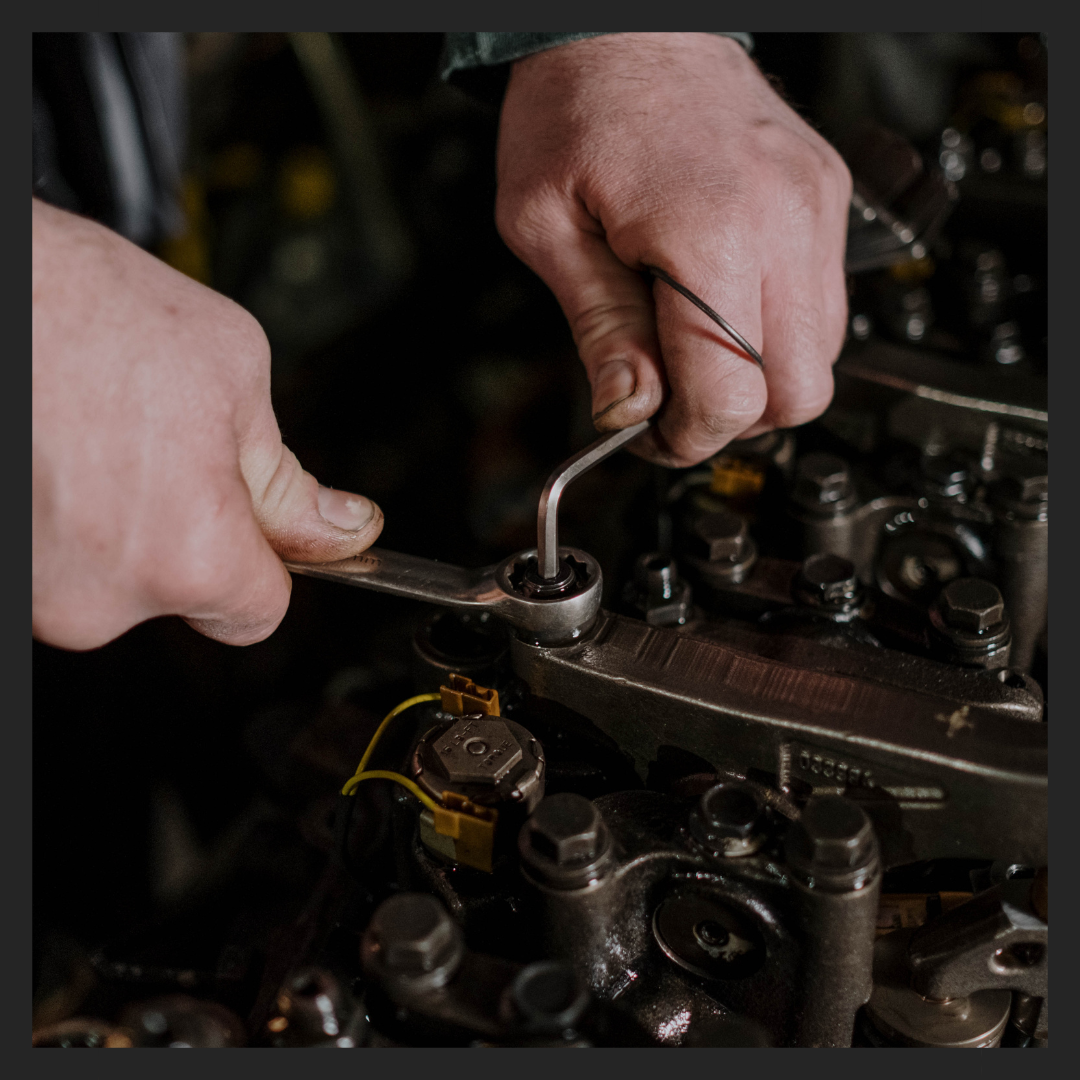

Importance of Proper Assembly Techniques

Even the most well-designed rod and piston modifications can fail if not correctly assembled. Utilizing proper assembly techniques is paramount to ensuring longevity. For instance, employing suitable lubricants during installation can reduce friction at startup and allow for smoother operation. Additionally, adhering to the correct torque specifications for connecting rods and piston bolts prevents joint failure, which is crucial for long-term performance. This emphasis on assembly integrity can significantly extend engine lifespan while ensuring that the performance benefits from the rod and piston work are fully realized.

Rod and piston work are essential elements in enhancing engine performance and longevity. Whether you’re replacing connecting rods or optimizing piston configurations, having the right tools and components is vital for achieving desired results. Trust in our decades of experience and commitment to quality—because when it comes to your engine, every detail counts.