Precision Valve Seat Grinding for High-Performance Engine Rebuilds

Feb 4th 2026

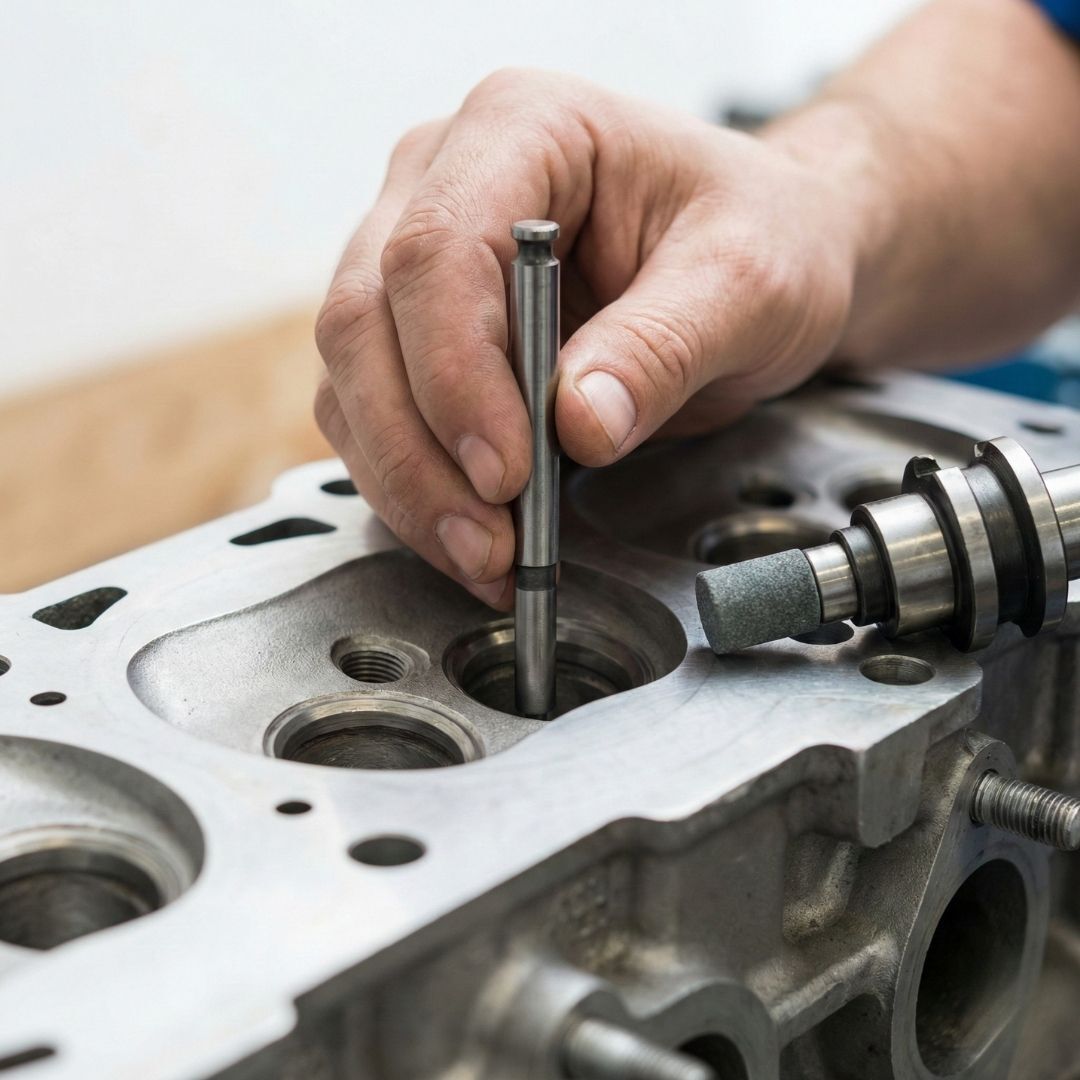

Achieving a perfect seal between the valve and the seat is critical for maintaining compression and optimizing airflow in any performance engine. While many focus on the hardware, the precision of your seat work dictates the longevity and efficiency of the build. We understand the nuances required to achieve race-ready results in your shop.

The Role of Concentricity in Seat Geometry

Achieving perfect concentricity is non-negotiable when we aim for maximum performance. Even minor deviations can cause premature wear or catastrophic valve failure at high RPMs. We provide specialized pilots and drivers that ensure your grinding stones remain perfectly centered. This level of precision eliminates chatter and creates the consistent surface finish essential for a leak-free combustion chamber seal.

Selecting the Proper Abrasive Grade

Not all seat materials respond the same way to standard abrasives. Whether we are working with hardened steel inserts or vintage cast iron heads, selecting the correct wheel grit is paramount. Our extensive inventory of grinding wheels allows for aggressive stock removal or fine finishing, ensuring that every seat meets the specific tolerances required for your high-performance application.

Managing Thermal Expansion During Grinding

Heat management is a critical factor often overlooked during the seat grinding process. Excessive friction can lead to localized hardening or surface cracking, compromising the integrity of the cylinder head. We recommend using high-quality lubricants to dissipate heat and clear debris. This practice maintains the sharpness of the abrasive while ensuring the metal stays within safe thermal limits.

Validating Your Seal with Vacuum Testing

Once the grinding is complete, we must verify the integrity of our work. Relying solely on visual inspection is risky for advanced builders. Utilizing a vacuum tester allows us to confirm a perfect seal without the mess of traditional liquid tests. It provides immediate feedback, ensuring that every valve is seated correctly before the final engine assembly begins.

Mastering the intricacies of valve seat geometry requires the right combination of skill and professional-grade equipment. By focusing on concentricity, abrasive selection, and thermal management, we ensure that every engine build achieves its full power potential. At Regis Manufacturing, we are dedicated to providing the specialized tools and supplies that advanced engine builders trust. If you are looking to upgrade your shop’s capabilities, explore our full catalog of seat grinding tools or contact us for technical specifications.