Our Guide to Engine Block Resurfacing Best Practices

Jun 25th 2025

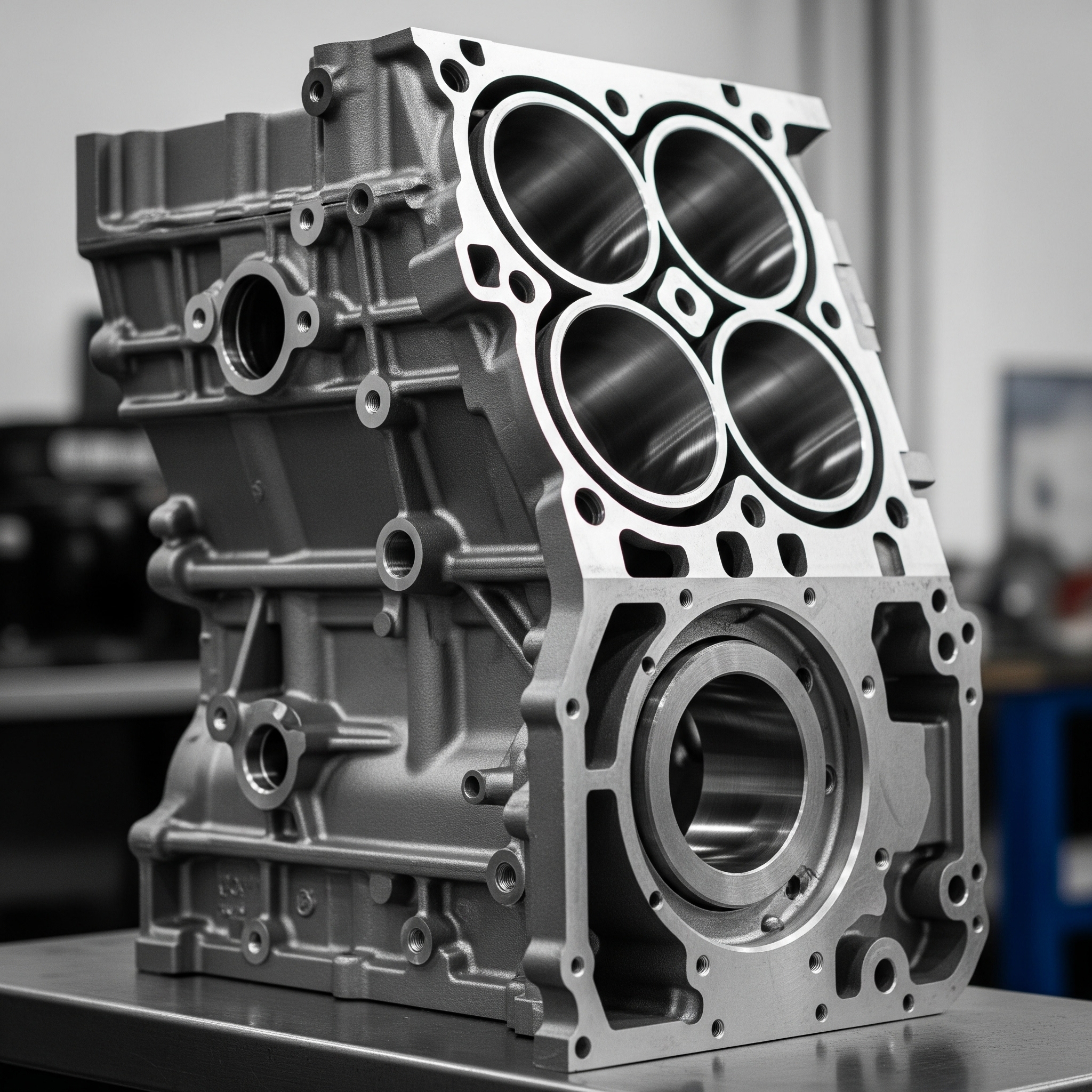

At Regis Manufacturing, we’ve seen firsthand how critical a perfectly flat engine block is to engine performance and longevity. For over six decades, we have been a trusted partner to the engine building industry, providing the high-quality tools and expertise needed for every aspect of engine work. When it comes to engine block resurfacing, precision isn't just a goal; it's a necessity. We believe that mastering this process is fundamental for achieving an optimal seal and preventing costly engine failures down the line.

Why Engine Block Resurfacing is Essential

Engine blocks can warp or become uneven over time due to heat and stress, leading to head gasket leaks and compromised performance. Resurfacing meticulously restores the block's mating surface to a perfectly flat plane. This ensures a tight, reliable seal with the cylinder head, which is absolutely vital for maintaining proper compression and preventing coolant or oil leaks. Our commitment at Regis Manufacturing is to help you achieve this critical flatness.

Pre-Resurfacing Preparation: A Crucial Step

The Right Tools for Precision Resurfacing

Post-Resurfacing Care and Inspection

Once the resurfacing is complete, the work isn't over. A thorough post-machining cleaning is necessary to remove any metal shavings or debris. Critical final inspections, including re-checking flatness and surface finish, are paramount before assembly. At Regis Manufacturing, we advocate for these diligent steps to guarantee that the engine block is truly ready for reassembly, ensuring peak performance and reliability.

Since our establishment in 1959, Regis Manufacturing has been dedicated to empowering engine builders with the best tools and knowledge. We understand that mastering engine block resurfacing best practices is fundamental to building reliable, high-performance engines. By focusing on precision, proper preparation, and the right tools, you can ensure the longevity and efficiency of every engine you work on. Explore how Regis Manufacturing can support your next project with our extensive range of quality products and expert advice.