Crankshaft Belt Grinding & Cleaning: Maintaining Engine Balance

Apr 29th 2025

At Regis Manufacturing, we know that a well-functioning engine starts with well-maintained components, particularly the crankshaft. Proper crankshaft maintenance is essential for achieving engine balance and preventing costly repairs. Here are some valuable tips on crankshaft belt grinding and cleaning to keep your engine running smoothly.

Understanding Engine Balance

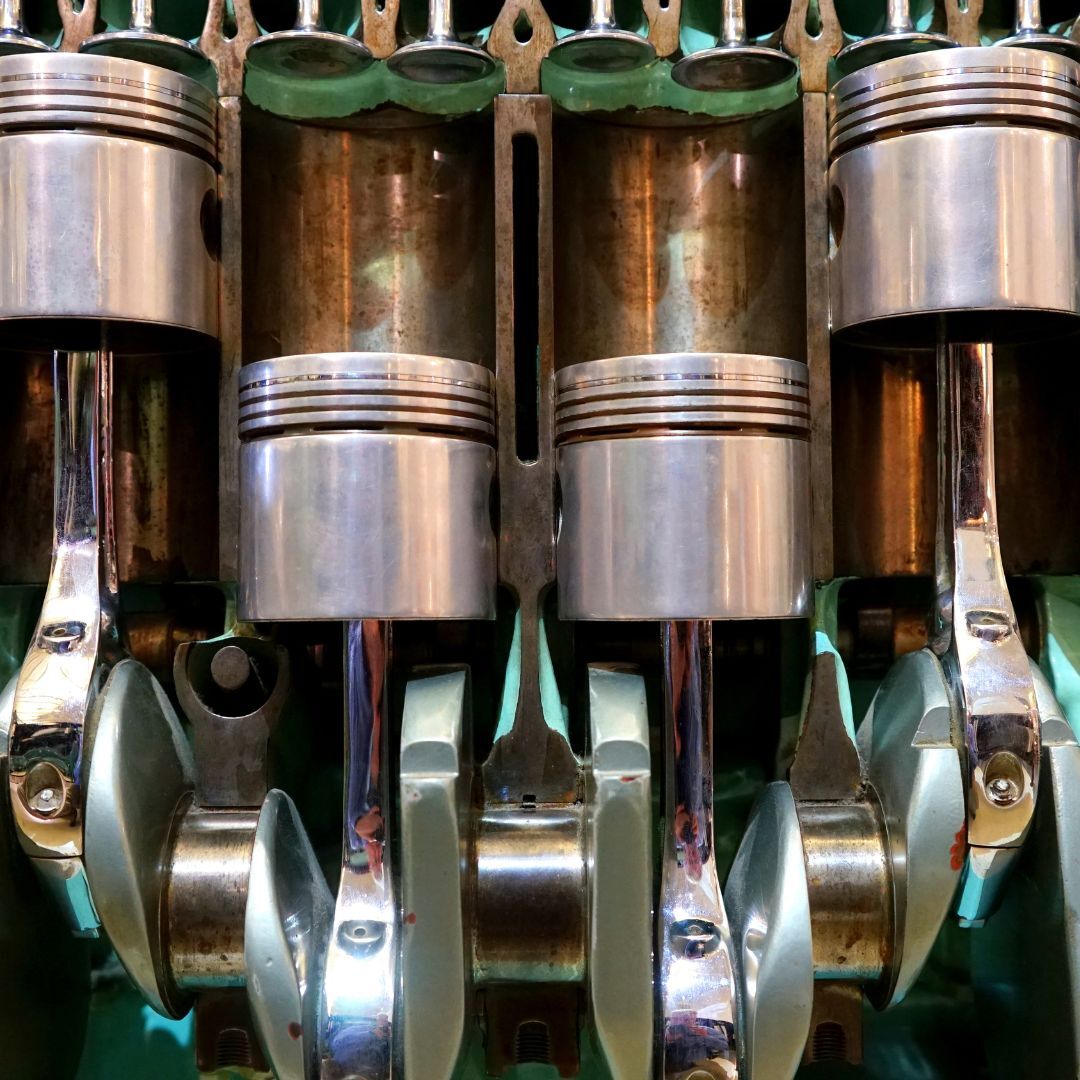

Before diving into maintenance tips, it’s essential to understand the role of the crankshaft in engine performance. The crankshaft converts linear motion from the pistons into rotational energy, contributing to engine balance. An unbalanced crankshaft can lead to vibrations, reduced efficiency, and accelerated wear on engine parts. Maintaining a properly balanced crankshaft is crucial for optimal engine operation.

Regular Inspection and Grinding

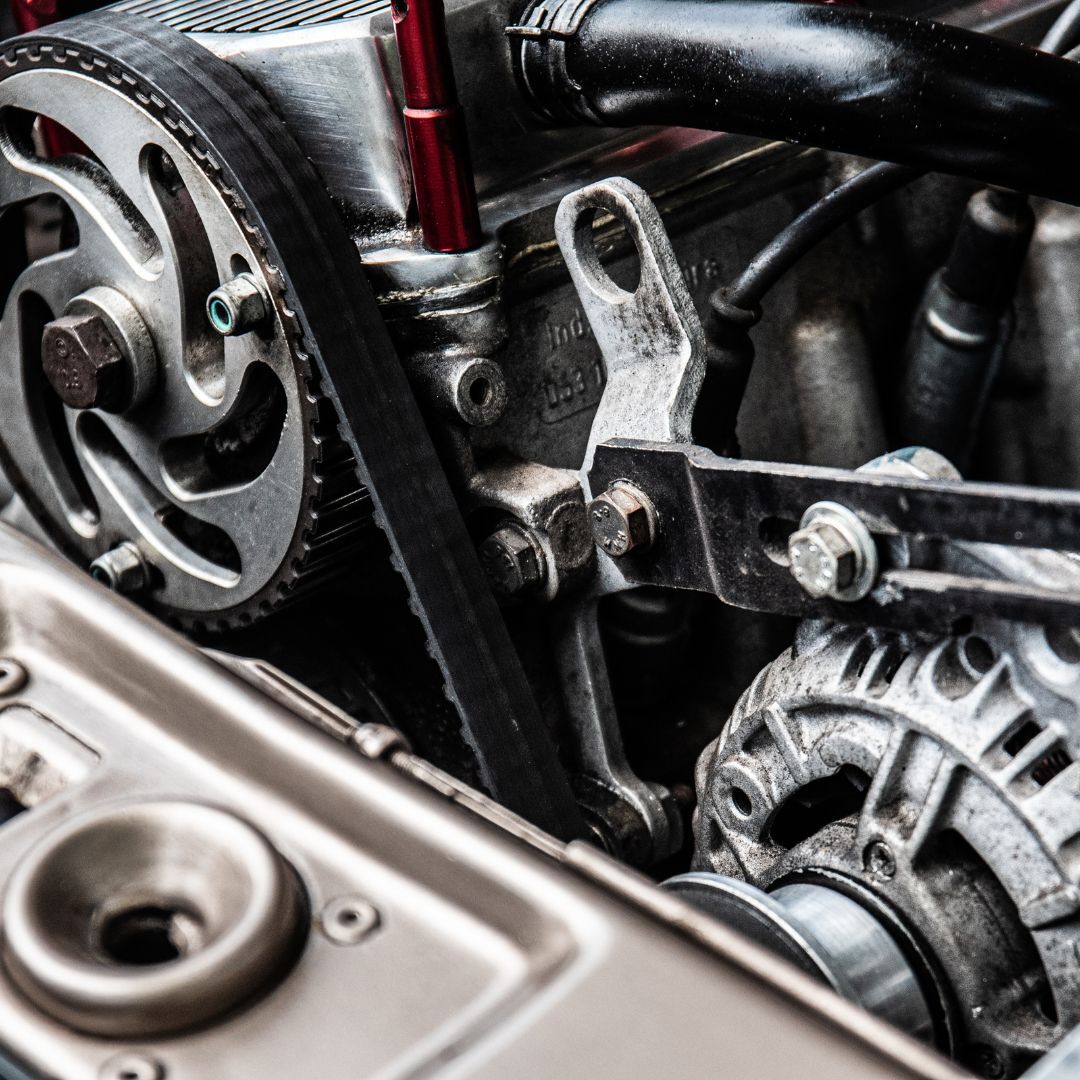

One of the best practices in crankshaft maintenance is regular inspection. Look for signs of wear, including scoring or rough surfaces. If the crankshaft shows damage, belt grinding should be performed to restore its surface quality. Grinding helps maintain the crankshaft's precision tolerances, reducing vibrations and enhancing performance. Consult your engine’s specifications to determine the appropriate grinding intervals.

Effective Cleaning Techniques

Contaminants like oil residue, dirt, and metal shavings can accumulate over time, affecting balance and engine performance. Use appropriate cleaning solutions and methods, such as solvent cleaning or ultrasonic cleaning, to ensure that the crankshaft is free from debris. Regular cleaning helps maintain the integrity of the crankshaft and prevents issues that could affect engine balance.

Preventative Measures

To prevent premature wear on your crankshaft, consider implementing routine oil changes and using high-quality lubricants. This helps reduce the buildup of harmful deposits and keeps the crankshaft operating smoothly. Additionally, ensure that all engine parts, including bearings and seals, are in good condition to support overall engine performance.

At Regis Manufacturing, we supply high-quality crankshaft parts designed for durability and performance. By following these maintenance tips, you can help ensure that your engine operates at its best for years to come. If you're looking for reliable crankshaft components, reach out to us!