Beyond the Torque Wrench: The Unsung Heroes of a Precision Rebuild

Dec 9th 2025

At

Precision Ring Gapping

File-to-fit piston rings are standard in high-performance applications, but achieving the perfect end gap requires precision. Our piston ring squaring tools are essential for getting an accurate measurement in the bore before you ever touch a file. Once measured, a purpose-built piston ring filer, preferably with a carbide wheel, is the only way to ensure a square, clean cut without damaging the ring coating.

The Final Clean

You've cleaned the block after machining, but have you cleaned it for assembly? The level of cleanliness required for final assembly is surgical. We recommend a dedicated set of engine brushes in various sizes to reach every oil gallery and crevice one last time. Any remaining microscopic debris will find its way into a bearing, and that’s a risk no professional builder should take.

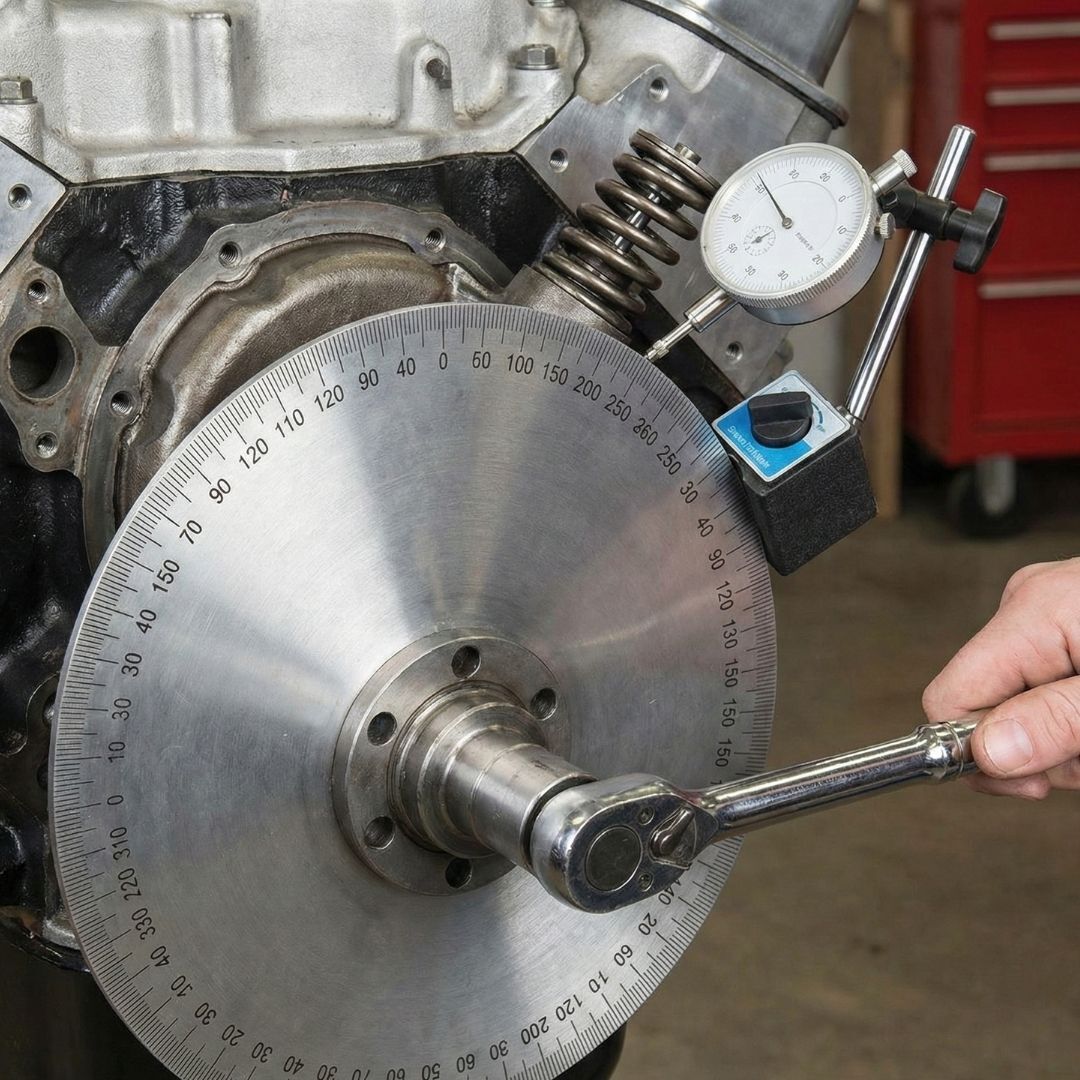

Degreeing for Power

Installing a camshaft "straight up" is rarely sufficient for a performance build. To unlock the full potential of your valve train, you must verify camshaft timing relative to crankshaft position. A large diameter, easily readable degree wheel combined with a rigid crank socket for turning the assembly is the industry standard for performing this critical validation.

The Harmonic Balancer Press

Hammering a harmonic balancer onto a crankshaft snout is a rookie mistake that can damage the crank's thrust bearing and the balancer itself. The only acceptable method is using a dedicated installation tool. This tool threads into the crank snout and uses a bearing-supported nut to gently and evenly press the balancer into place, ensuring zero damage to your precision components.

Protecting Your Investment at First Fire

The initial startup is the most critical moment for a fresh engine. To prevent immediate bearing and cam lobe failure before oil pressure builds, a high-quality, semi-synthetic engine assembly lube is non-negotiable. Look for formulas rich in Zinc and Moly high-pressure additives that adhere to metal surfaces, providing a sacrificial barrier against galling during those vital first rotations.

Professional Assembly Starts Here

Don't compromise a blueprint build with subpar final steps. From precision measuring tools to critical protective lubricants, Regis Manufacturing offers the professional Assembly Supplies you need to complete the job with confidence. Explore our