The Benefits of Using Diamond Tools in Engine Building

Feb 11th 2025

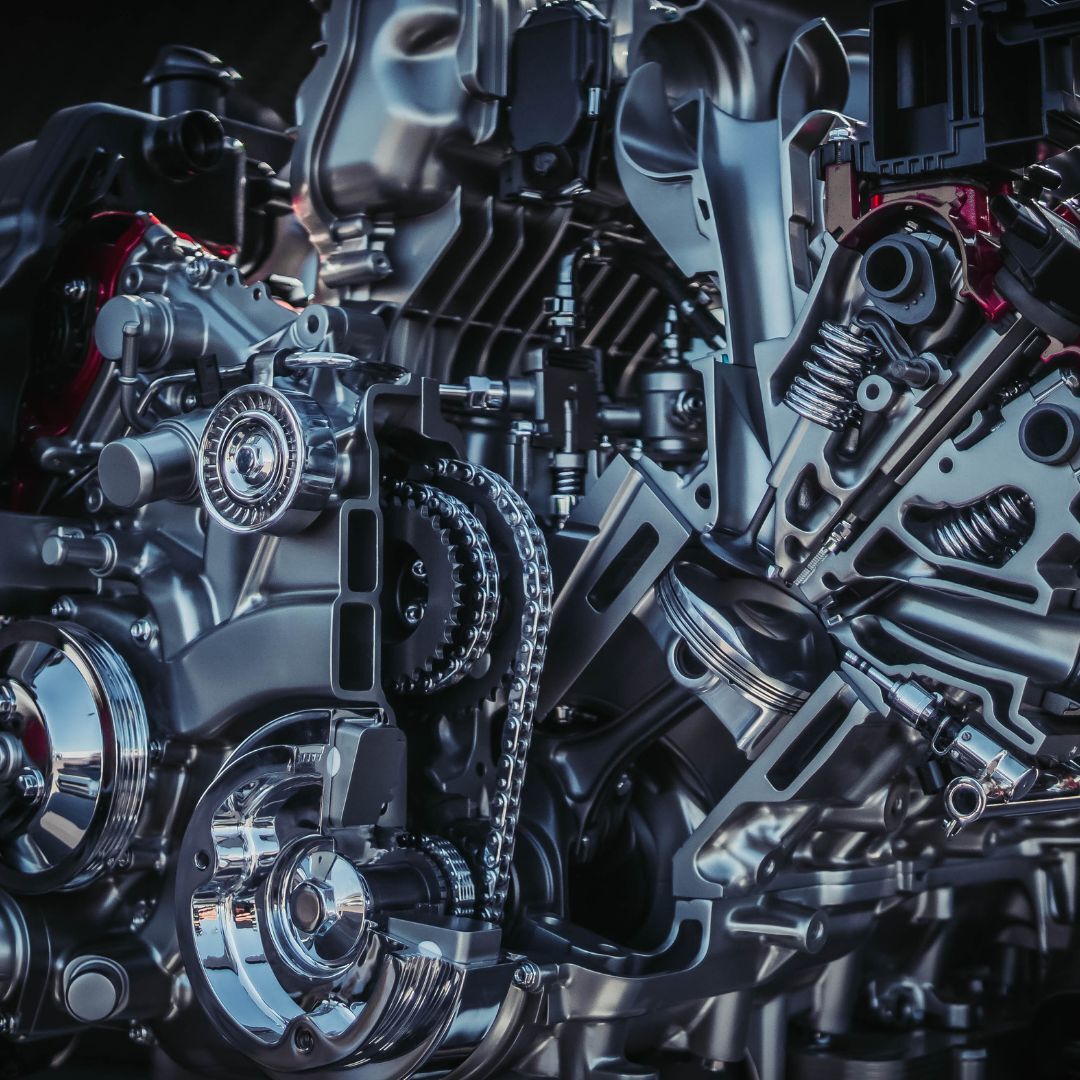

In the precise world of engine building, utilizing the right cutting tools can significantly impact performance outcomes. Diamond tools, known for their unparalleled hardness and durability, offer distinct advantages over conventional cutting tools. At Regis Manufacturing, we provide a selection of high-quality diamond tools tailored to meet the stringent demands of engine builders. This article explores the key benefits of using diamond tools in engine building to enhance precision and elevate engine performance.

Unmatched Hardness for Superior Precision

Diamond tools are recognized for their superior hardness, which allows them to maintain sharp cutting edges over extended periods. This characteristic translates to precise cuts with minimal wear, resulting in increased accuracy during machining operations. Engine builders can rely on diamond tools to achieve tighter tolerances, which is critical for optimal engine performance.

High Melting Point: Enhanced Thermal Stability

One of the significant advantages of diamond tools is their high melting point, which allows them to withstand the extreme temperatures often generated during engine machining. This thermal stability minimizes the risk of tool deformation or failure, ensuring consistent performance throughout the machining process. For engine builders, this means increased tool longevity and reduced downtime for tool changes.

Superior Chip Removal for Efficient Machining

The design of diamond tools promotes efficient chip removal, an essential factor in maintaining cutting effectiveness. Improved chip clearance minimizes the risk of re-cutting chips, which can lead to tool damage and poor surface finishes. By using diamond tools, engine builders can achieve a cleaner and more efficient machining process, resulting in higher quality engine components.

Versatility in Material Compatibility

Diamond tools are effective on hard materials and versatile enough to work with various substrates commonly used in engine building. Regardless of machining aluminum, titanium, or ferrous materials, diamond tools deliver consistent performance across applications. This versatility makes them an invaluable asset for any engine builder aiming to achieve remarkable results across diverse projects.

Elevate Your Engine Building with Diamond Tools

In the competitive landscape of engine building, the choice of cutting tools can mean the difference between subpar performance and exceptional results. Diamond tools from Regis Manufacturing provide the precision, durability, and efficiency that modern engine builders require. With our extensive range of diamond cutting tools designed for superior performance, you can elevate your engine building projects to new heights. Shop our offerings today and experience the benefits of diamond tools for yourself!